Drilling and milling machine FM 55 HSV incl. 3-axis digital readout ES-12 V and feeder for x-axis

Art. No.: 02-1097The drilling and milling machine FM 55 HSV feature a solid construction and practicality. Making this model truly versatile is the standard equipment which comprises all major accessories such as 3-axis position readout, table feed, lifting motor, central lubrication, coolant device, LED working light, cast iron stand with coolant groove and safety precautions in accordance with CE-standards.

€6,768.00

Availability

Product Properties

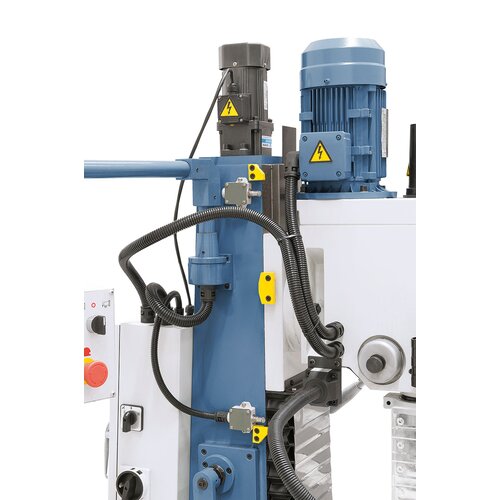

- Serially equipped with automatic spindle feed and thread cutting device

- Automatic table feed with rapid feed allows quick table adjustment in x-axis

- Solid, grey cast-iron machine stand eliminates vibrations

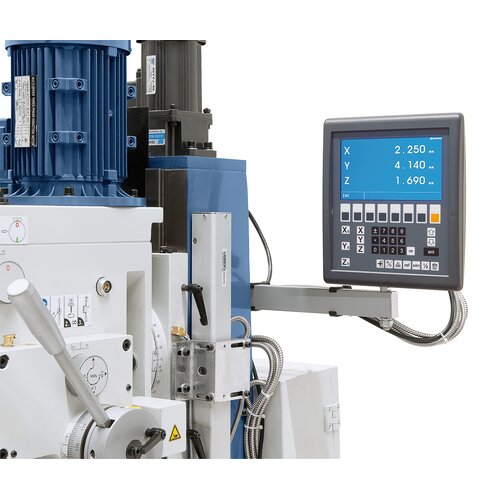

- Complete with digital readout in all three axis to increase productivity

- 2-speed-motor with 12 speed settings (75 - 3200 rpm)

- Wide range of applications, such as horizontal slotting, face milling, reboring

- Mill head tilts to both sides for angular boring, milling of bevels etc.

- Lifting motor allows convenient height adjustment of mill head

- Dovetail guiding in x-, y- and z-axis, adjustable by gibs

- Dovetail guiding of gear head maximizes stability

- Manual central lubrication for all guide ways

Product Specifications

|

Drilling capacity in steel |

32 mm |

|

Drilling capacity in cast iron |

40 mm |

|

Milling head max. |

80 mm |

|

Distance spindle to column |

220 mm |

|

Spindle speeds |

(12) 75 – 3200 rpm |

|

Spindle taper |

MT 4 |

|

Spindle stroke |

120 mm |

|

Spindle feed |

(3) 0,10 / 0,18 / 0,26 mm/rev. |

|

Table size |

800 x 240 mm |

|

Travel (x / y) |

420 / 200 mm |

|

Mill head tiltable |

-60° to +60° |

|

Distance spindle to table |

95 - 485 mm |

|

Height adjustment of mill head |

390 mm |

|

T-slot size |

14 mm |

|

Lifting motor |

90 W |

|

Motor power output S1 100% |

1,1 / 1,5 kW (400 V) |

|

Motor power input S6 40% |

1,5 / 2,2 kW (400 V) |

|

Machine dimension (W x D x H) |

1270 x 960 x 2120 mm |

|

Weight approx. |

447 kg |

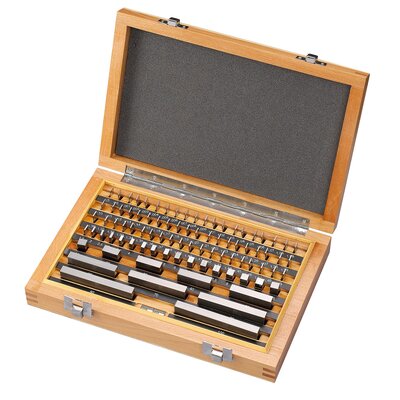

Delivery Contents

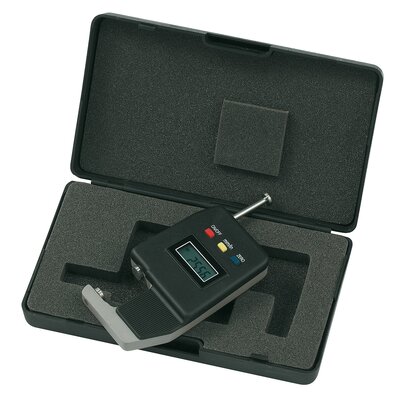

- 3-axis digital readout ES-12 V with LCD-display

- Keyless drill chuck 3 – 16 mm / B 16

- Drill chuck arbor MK 4 – B 16

- Drawbar M 16

- Morse taper drill sleeve MT 4 / 3

- Taper shell end mill holder MT 4 / 27 mm

- Automatic spindle feed

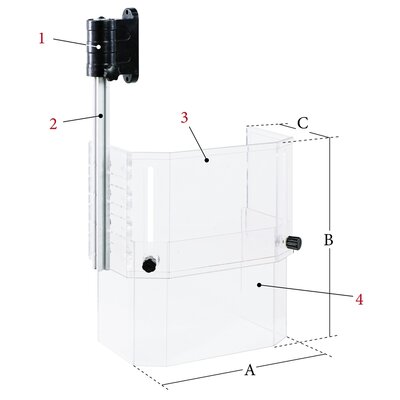

- Height adjustable protecive cover

- Lifting motor for mill head

- Central lubrication

- x-axis power feed AL 450 D

- LED machine light

- Digital spindle stroke indication

- Thread cutting device

- Steel cover

- Coolant device

- Longitudinal scale

- Cast iron stand with coolant groove

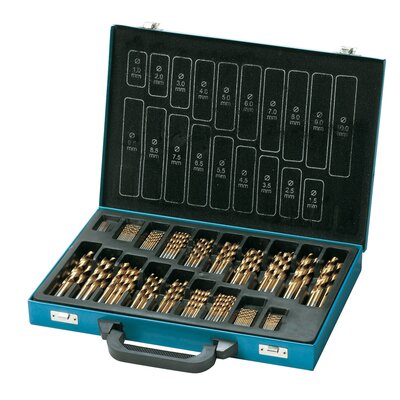

- Tools

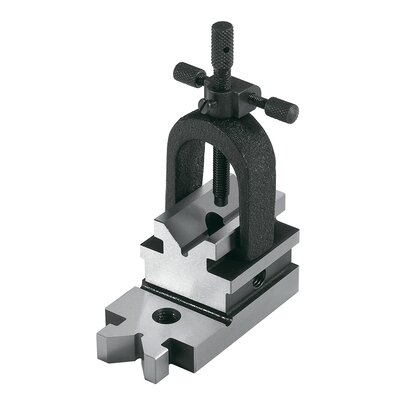

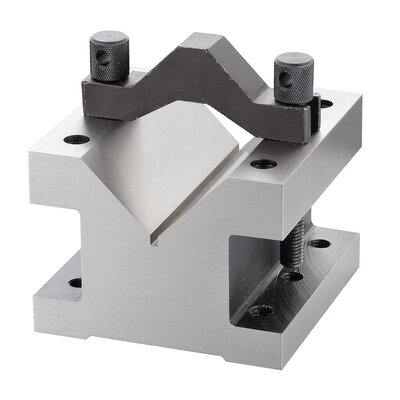

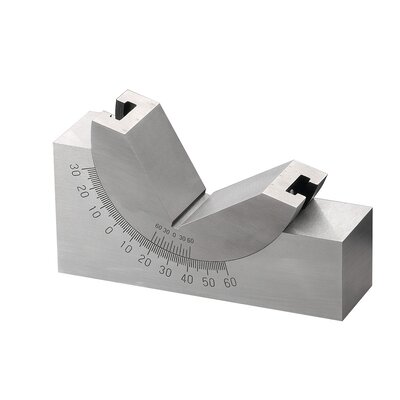

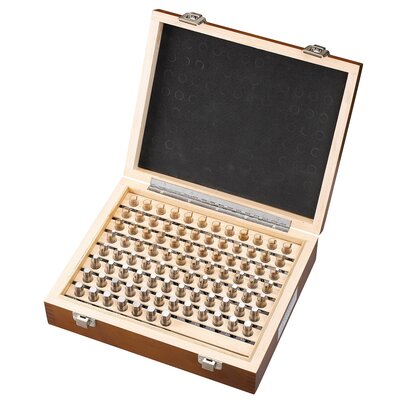

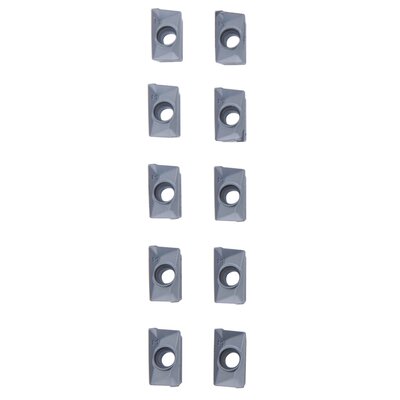

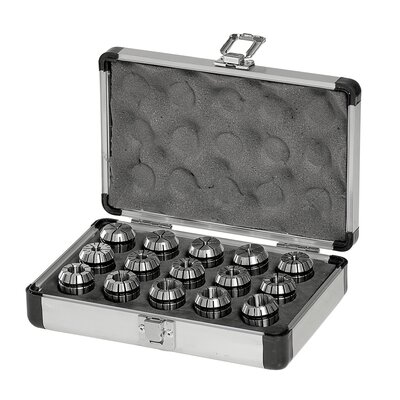

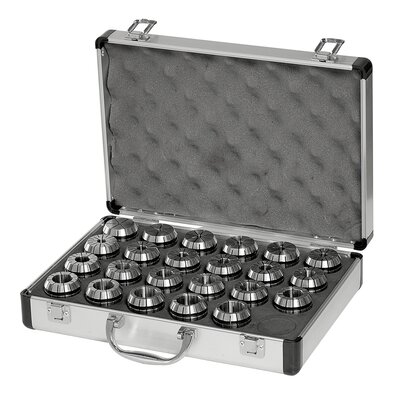

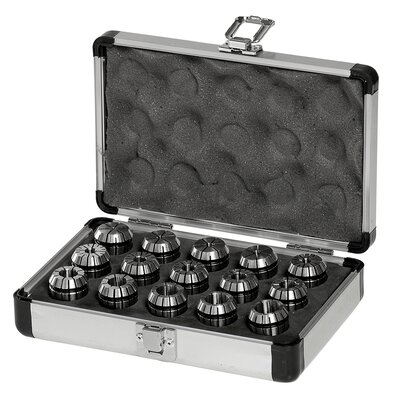

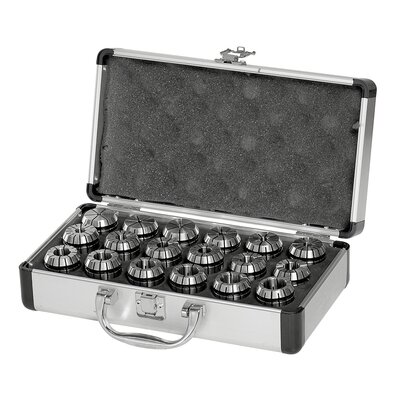

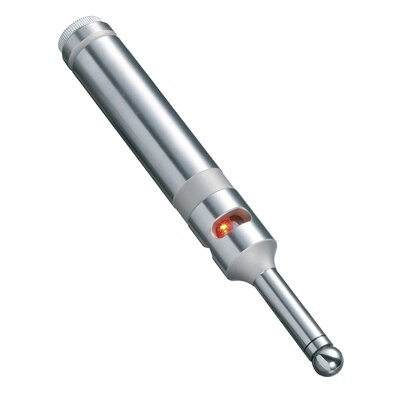

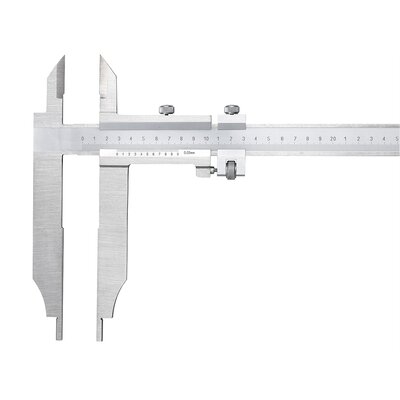

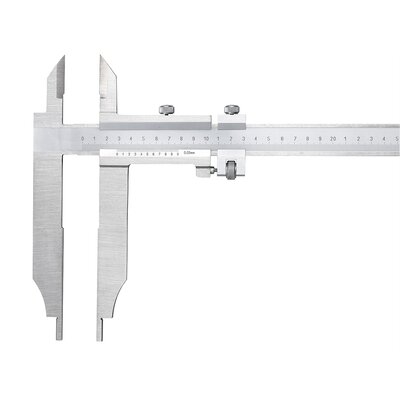

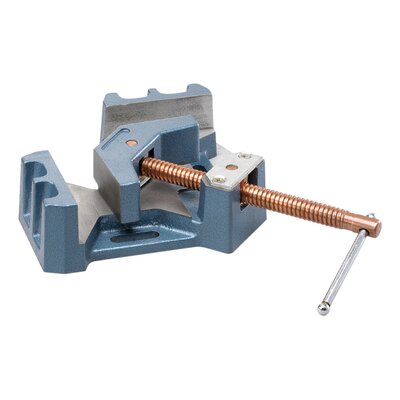

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.