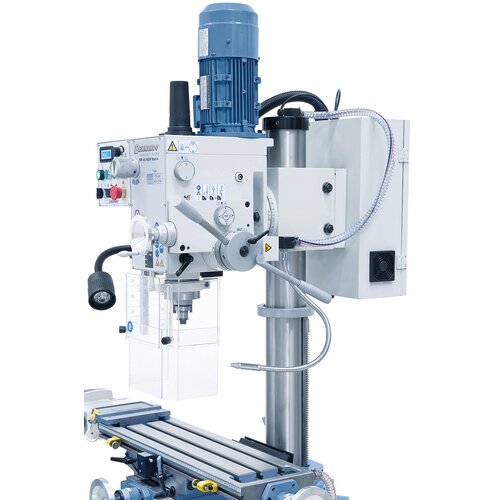

Drilling and milling machine BF 45 HSV Vario incl. power feeder for x-axis

Art. No.: 02-11080The drilling and milling machine BF 45 HSV Vario is suitable for drilling and milling in horizontal, vertical and inclined position. Due to the solid construction, serially spindle feed, digital spindle stroke indication and the stepless speed adjustment, this model is popular at model-makers, craftsmen and repair shops.

€4,280.00

Availability

Product Properties

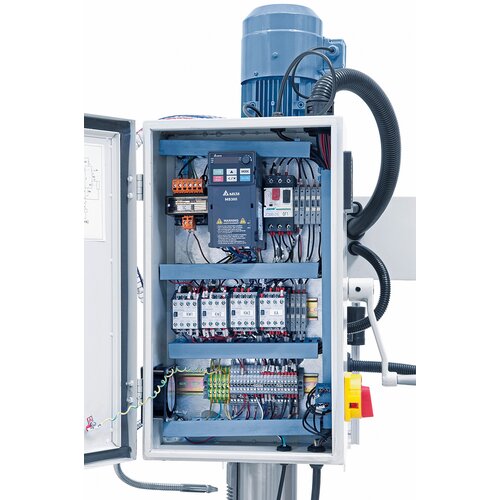

- Delta-frequency inverter ensures variable speed adjustment with optimal torque

- Height adjustable protective cover in accordance to CE standards for increased safety

- Many possible applications, such as groove milling, face milling, reboring etc.

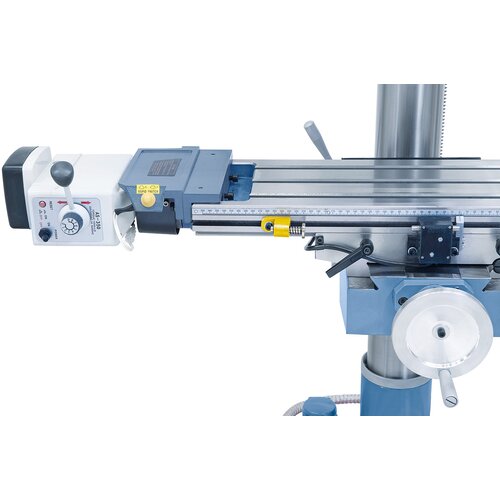

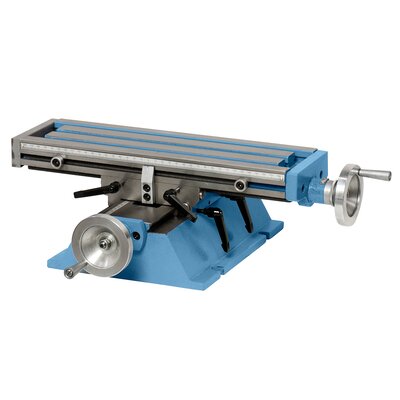

- Large cross table with T-slots and coolant groove

- Polished gear wheels, in oil bath, allow smooth running

- Digital display for speed and spindle stroke comes standard

- Mill head tilts to both sides for angular boring, groove milling and many more

- Dovetail guiding in x- and z-axis, adjustable by gibs

- Solid, polished steel column in heavy-duty design

- Comes complete with automatic spindle feed

- Left and right turning for thread cutting

Product Specifications

|

Drilling capacity in steel |

32 mm |

|

Drilling capacity in cast iron |

40 mm |

|

Milling head max. |

80 mm |

|

Distance spindle to column |

280 mm |

|

Spindle speed, stepless |

75 - 2750 rpm |

|

Spindle taper |

MT 4 |

|

Spindle stroke |

120 mm |

|

Spindle feed |

(3) 0,10 / 0,18 / 0,26 mm/r |

|

Table size |

730 x 210 mm |

|

T-slot size |

14 mm |

|

Distance spindle to table max. |

640 mm |

|

Distance spindle to base plate max. |

1190 mm |

|

Travel (x / y) |

495 / 200 mm |

|

Mill head tiltable |

-90° to +90° |

|

Height adjustment of mill head |

260 mm |

|

Column diameter |

115 mm |

|

Base plate |

365 x 375 mm |

|

Motor power output S1 100% |

1,5 kW (400 V) |

|

Motor power input S6 40% |

2,2 kW (400 V) |

|

Machine dimension (W x D x H) |

1070 x 800 x 2060 mm |

|

Weight approx. |

362 kg |

Delivery Contents

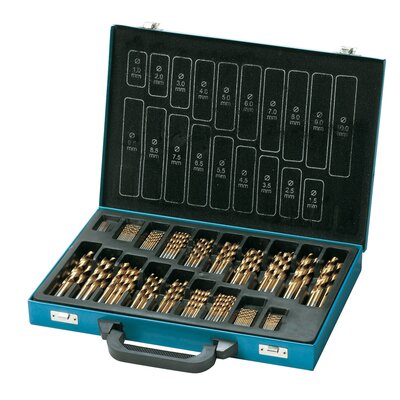

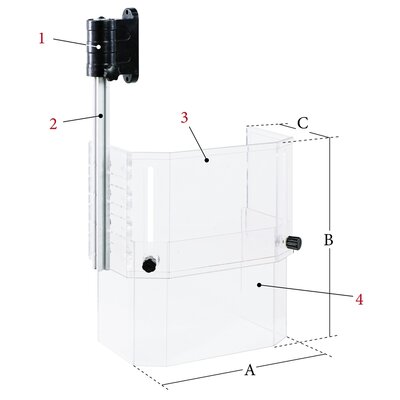

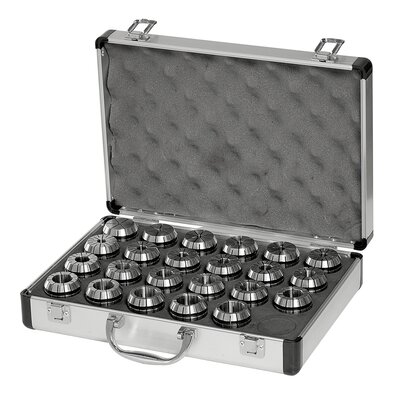

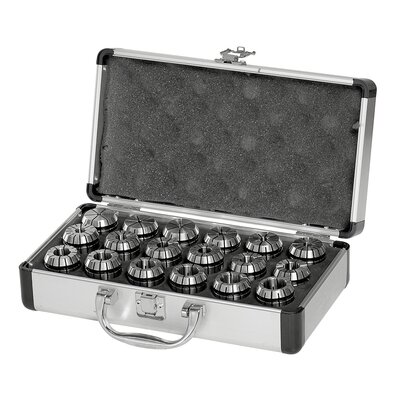

- x-axis power feed AL 450 D

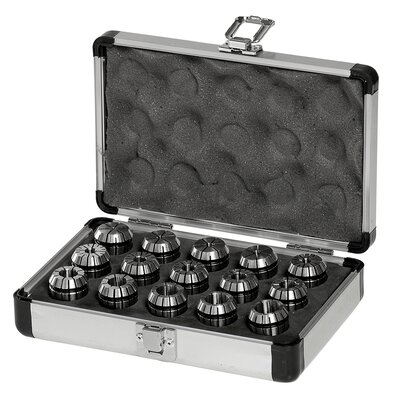

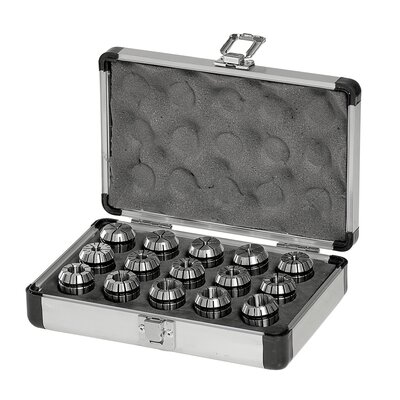

- Keyless drill chuck 1 – 16 mm / B 16

- Drill chuck arbor MT 4 / B 16

- Drawbar M 16

- Morse taper drill sleeve MT 4 / 3

- Taper shell end mill holder MT 4 / 27 mm

- Automatic spindle feed

- Height adjustable protective cover

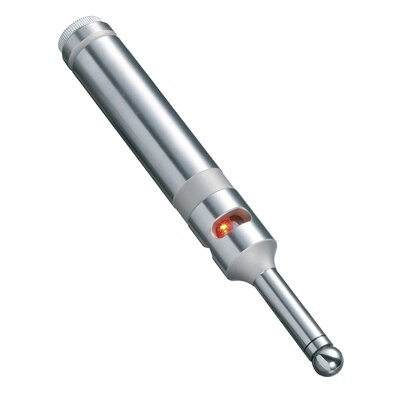

- Digital spindle stroke indication

- Digital speed indication

- Frequency inverter

- Thread cutting device

- Coolant device

- LED machine light

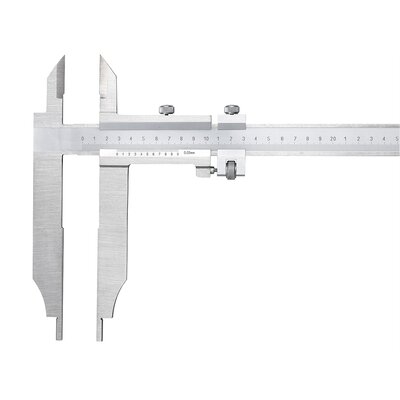

- Longitudinal scale

- Tools

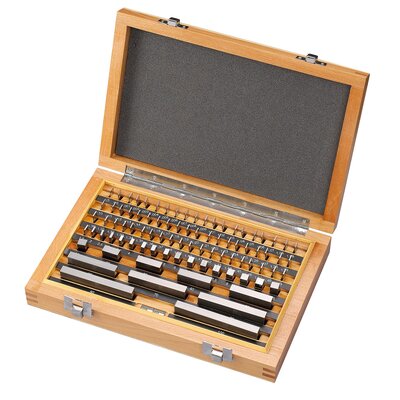

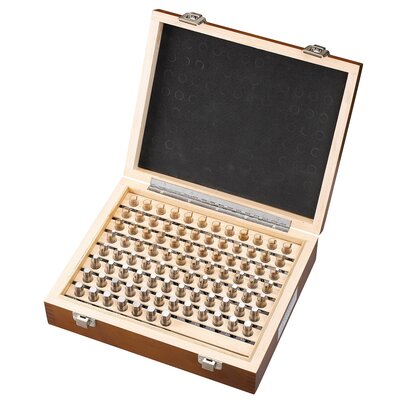

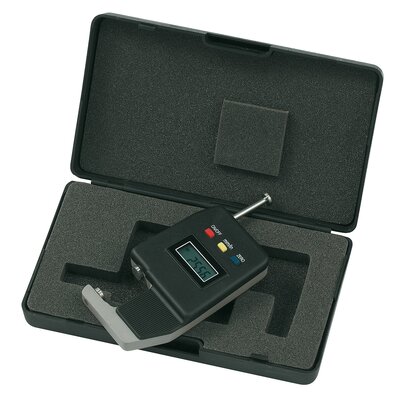

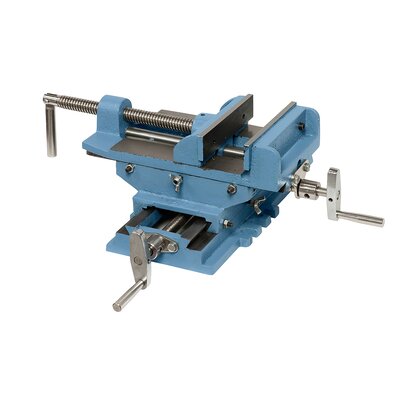

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.