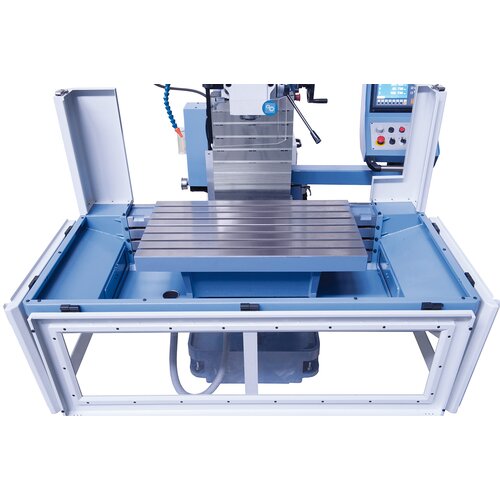

Universal-tool room milling machine TRM 900 incl. 3-axis digital readout **

Art.Nr.: 02-1327XLThe TRM 900 universal milling machine is suitable for milling works ranging from a low to a medium level of difficulty. The standard equipment of this model allows for horizontal, vertical and inclined milling works. This machine is mainly used in tool and mould construction, in model making and for training purposes.

Price on request

Request product nowAvailability

Product Properties

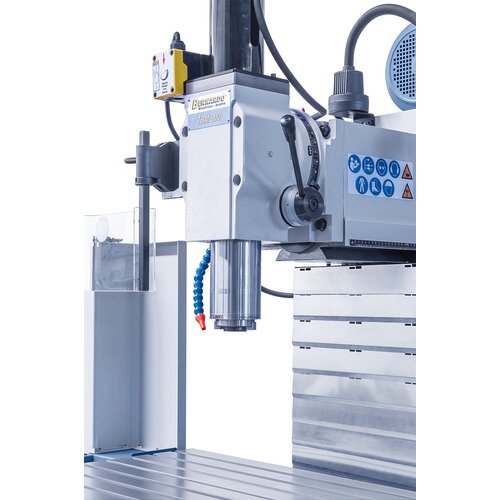

- Serially with hydraulic tool clamping for quick tool changing

- Ball screws in all three axis minimize play

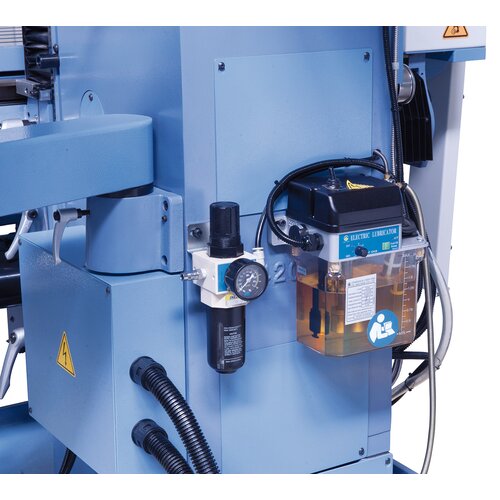

- Electrical central lubrication for the guideways comes standard

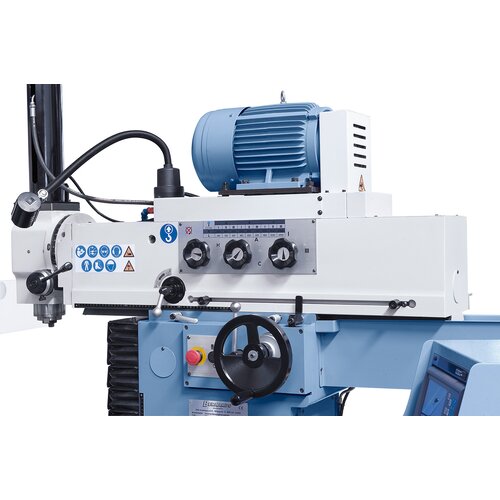

- Complete with manual, automatic and rapid feed in all three axis

- Vertical clamping area with 3 T-slots allows clamping of work table, universal tilting table and oversize workpieces

- Clearly arranged spindle speed control unit on machine arm

- Large dovetail guiding in x- and y-axis, rectangular guiding in z-axis

- Feeding speed adjustable by frequency inverter

- Swiveling mill head for horizontal milling

- Solid grey cast-iron machine base guarantees precision and minimizes vibrations

Product Specifications

|

Table size |

900 x 500 mm |

|

Vertical clamping surface |

1200 x 250 mm |

|

Travel longitudinal (x) |

560 (600*) mm |

|

Travel cross (y) |

440 (480*) mm |

|

Travel vertical (z) |

345 (385*) mm |

|

Table load |

360 kg |

|

Vertical milling head |

|

|

Spindle speed |

(18) 40 - 2000 rpm |

|

Spindle taper |

SK 40 / DIN 69871A |

|

Spindle stroke |

120 mm |

|

Distance spindle to column max. |

550 mm |

|

Distance spindle / table |

40 - 440 mm |

|

Spindle head tilting range |

-90° to +90° |

|

Horizontal milling head |

|

|

Spindle speed |

(18) 40 - 2000 rpm |

|

Spindle taper |

ISO 40 |

|

Distance spindle / table |

130 - 530 mm |

|

Feeding speeds |

|

|

x-axis |

10 - 450 mm/min |

|

y-axis |

10 - 450 mm/min |

|

z-axis |

10 - 450 mm/min |

|

Rapid feed (x / y / z) |

680 mm/min |

|

T-slot (quantity / width / distance) |

7 / 14 mm / 63 mm |

|

T-slot vertical table (quantity / width / distance) |

3 / 14 mm / 63 mm |

|

Feeding motor |

0,75 kW |

|

Main motor |

3,75 kW |

|

Machine dimension (B x T x H) |

1850 x 2135 x 2030 mm |

|

Weight approx. |

1700 kg |

* manual

Delivery Contents

- 3-axis digital readout ES-12 H with LCD-display

- LED machine light

- Coolant device

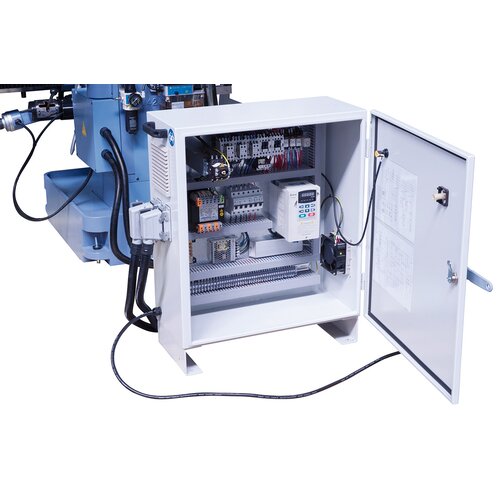

- Power feed for x-, y- and z-axis

- Horizontal counter bearing

- Table housing

- Ball screw in all 3 axis

- Hydraulic tool clamping

- Electrical central lubrication

- Frequency inverter Delta for power feeds

- Steel cover

- Long milling arbor ISO 40/27 mm

- Adapter SK 40 / MT 3

- Morse taper drill sleeve MT 3 / 2

- Morse taper drill sleeve MT 3 / 1

- Collet chuck SK 40 with collets 5 - 25 mm (7 pcs.)

- Tools

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.