Radial drilling machine RD 2500 NC Vario *

Art. No.: 01-1330XL0The radial drilling machine RD 2500 NC Vario is highly suitable for drilling, countersinking and reaming of oversize workpieces, such as steel girders, flanges etc. The special features of this model are the operation via a large touchscreen and the spindle feed by a servo motor. The wide range of applications makes this model ideal for mechanical workshops, repair shops, machine construction and many more.

€66,480.00

Availability

Product Properties

- The standard Bohrtronic control calculates the ideal speed or feed rate for drilling and thread cutting after entering the tool diameter and material (cast iron / steel)

- Large touchscreen for all settings, such as speed, drilling / thread cutting, height adjustment of support arm,….

- The quill feed takes place by a high quality servo motor

- Lifting motor ensures easy height adjustment of radial arm keeping the spindle in position – ideal for repetitive operations

- Electronically adjustable drill depth including checking of the input value

- Complete with stepless speed, set speed is visible on digital display

- Display of the measurements either mm or inch

- Guiderails on radial arm are hardened and polished

- Counter weight on spindle to ensure optimal balance

- Ideal for drilling, countersinking, reaming and tapping

Product Specifications

|

Drilling capacity max. |

80 mm |

|

Thread cutting max. |

M60 |

|

Distance spindle to column min./max. |

465 - 2550 mm |

|

Vertical movement of the support |

790 mm |

|

Travel of drill head (horizontally) |

2095 mm |

|

Spindle stroke |

400 mm |

|

Morse taper |

MT 6 |

|

Spindle speeds |

30 - 192, 205 - 1400 rpm |

|

Feed range |

1 - 300 mm/min |

|

Distance spindle to box table |

290 - 1080 mm |

|

Distance spindle to base |

770 - 1560 mm |

|

Clamping area base |

2500 x 1250 mm |

|

Box table (L x W x H) |

850 x 580 x 500 mm |

|

Motor power |

7,5 kW |

|

Machine dimension (W x D x H) |

3590 x 1250 x 3560 mm |

|

Weight approx. |

7800 kg |

Delivery Contents

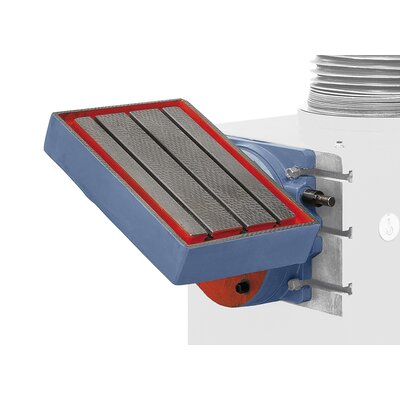

- Box table

- Drill chuck arbor

- Morse taper drill sleeve

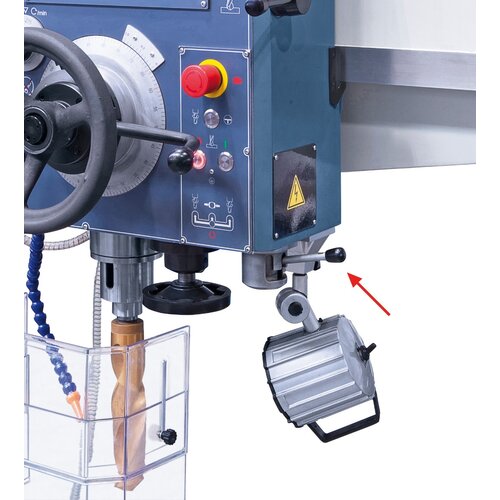

- LED machine light

- Initial filling with Shell Tellus 46

- Coolant device

- Frequency inverter

- Digital readout of speeds

- Lifting motor

- Hydraulic motor

- Height adjustable protective cover

- Tools

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.