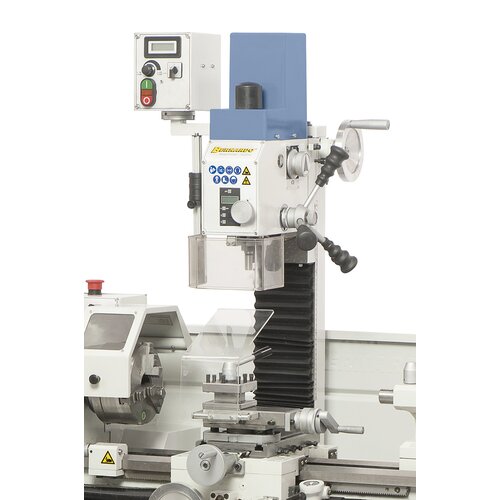

Vario-precision lathe Profi 700 BQV / 230 V incl. 2-axis-digital readout ES-12 V

Art. No.: Z-03-1173BThe vario turning lathe Profi 700 BQV is manufactured according to highest quality standards and precision. The ergonomically located digital display offers easy reading of the electronic speed adjustment. Special feature of this model include the large longitudinal feed with 14 settings and the cross feed. To reduce non-productive time the machine is equipped with a 2-axis digital readout.

€3,258.00

Availability

Product Properties

- Electronically adjustable, stepless speed setting comes standard

- Comes complete with feed rod for automatic longitudinal and cross feed

- Temperature monitoring incl. warning light protect motor against overload

- Standard 38 mm spindle bore

- High-quality tapered roller bearings ensure high concentricity of spindle nose (≤ 0.015 mm)

- Solid machine bed with inductive hardened and polished guideways

- Features leadscrew for thread cutting

- Top support can be adjusted in x-axis

- User-friendly arrangement of control elements

- Powerful motor, even at longer operation

- Tailstock adjustable for taper turning

- Guideways adjustable via gibs

Product Specifications

|

Distance between centers |

700 mm |

|

Center height |

140 mm |

|

Swing over bed |

280 mm |

|

Spindle bore |

38 mm |

|

Taper at spindle bore |

MT 5 |

|

Speed range, stepless |

50 - 850 / 110 - 1800 rpm |

|

Longitudinal feed |

(14) 0,07 - 0,65 mm/rev. |

|

Cross feed |

(11) 0,03 - 0,12 mm/rev. |

|

Metric thread |

(18) 0,2 - 3,5 mm |

|

Inch thread |

(21) 8 - 56 threads/1“ |

|

Travel of tailstock sleeve |

85 mm |

|

Taper of tailstock sleeve |

MT 3 |

|

Motor power output S1 100% |

1,1 kW / 230 V |

|

Motor power input S6 40% |

1,5 kW / 230 V |

|

Machine dimension (W x D x H)* |

1380 x 640 x 500 mm |

|

Weight approx. |

235 kg |

* without stand

Delivery Contents

- 2-axis digital readout ES-12 V with LCD-display

- 3-jaw chuck DK11-160 mm

- Flange 160 mm

- Dead center

- Change gears

- 4-way tool post holder

- Safety clutch

- Micrometer longitudinal fence

- Cross slide with top support

- Digital speed indication

- Thread dial

- Chuck guard

- Splash guard

- Spindle cover

- Tools

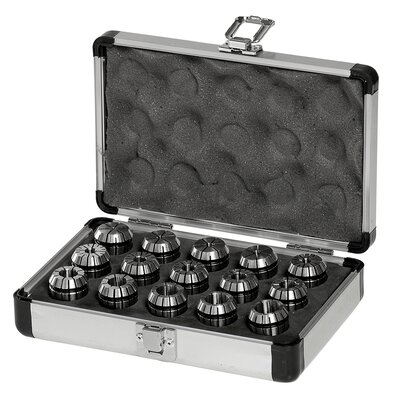

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.