Drilling and milling machine KF 25 L Vario

Art. No.: 02-1028The KF 25 L Vario drilling and milling machine comes complete with a digital speed and spindle stroke display as a standard feature. Additionally, this model is rounded off with a 490 mm x-axis travel. The machine is very popular among both professionals and model-marker along with all areas of training.

€2,076.00

Availability

Product Properties

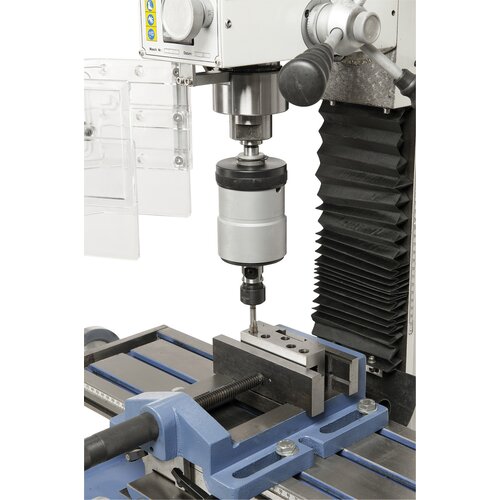

- Wide range of applications, such as thread cutting, groove milling, horizontal slotting etc.

- Left and right rotation for thread cutting comes standard

- Ergonomically arranged control elements

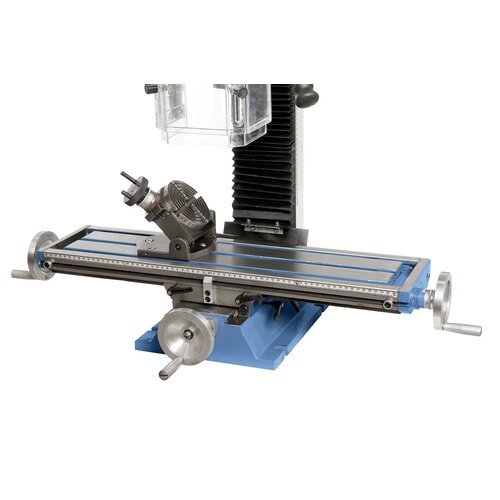

- Large cross table with scale

- Stepless speed change for ideal adjustment to the workpiece

- 2-step gear unit for optimal power transmission

- Taper roll bearings guarantee high spindle concentricity (≤ 0,015 mm)

- Mill head tilts to both sides allowing angular boring, milling of bevels etc.

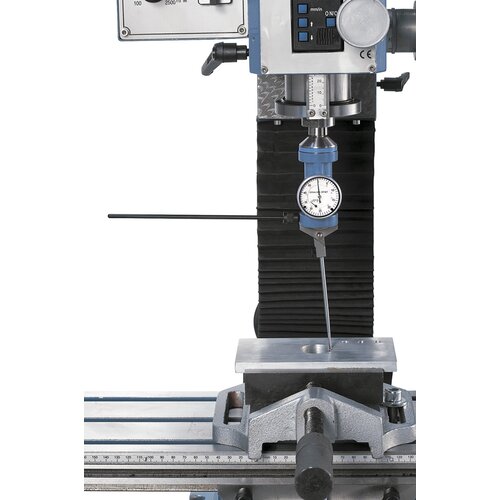

- Digital spindle stroke and speed display come standard

- Dovetail guiding in x-, y- and z-axis, adjustable via gibs

- Spindle adjustment via handle, fine feed via handwheel

- Incl. EMC filter; protect electrical equipment against electromagnetic interferences

Product Specifications

|

Drilling capacity in steel |

20 mm |

|

Face mill capacity max. |

63 mm |

|

End mill capacity max. |

20 mm |

|

Distance spindle to column |

170 mm |

|

Distance spindle/table min./max. |

45 / 325 mm |

|

Spindle stroke |

52 mm |

|

Spindle speed, stepless |

50 - 1125 / 100 - 2250 rpm |

|

Spindle taper |

MT 2 |

|

Table size |

700 x 180 mm |

|

Travel (x / y) |

490 / 150 mm |

|

Mill head tiltable |

-90° to +90° |

|

Height adjustment of mill head |

275 mm |

|

T-slot size |

12 mm |

|

Motor power output S1 100% |

0,60 kW / 230 V |

|

Motor power input S6 40% |

0,90 kW / 230 V |

|

Machine dimension (W x D x H)* |

950 x 560 x 930 mm |

|

Weight approx. |

120 kg |

* without stand

Delivery Contents

- Drill chuck arbor MT 2 / B 16

- Drawbar

- Table length 700 mm

- Digital display of spindle stroke

- Digital display of speed range

- EMC filter according to CE standard

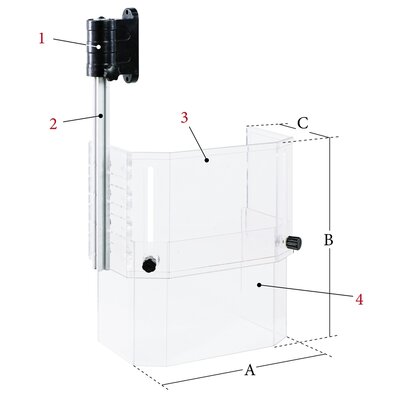

- Height adjustable protective cover

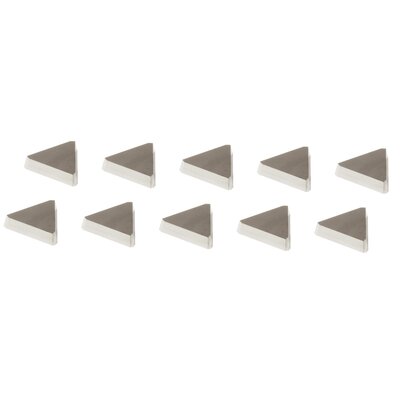

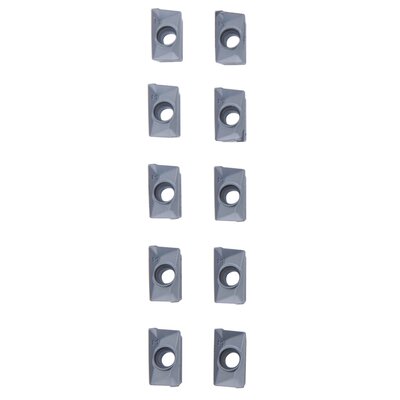

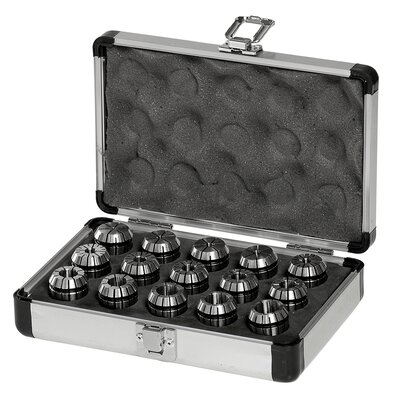

- Tools

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.