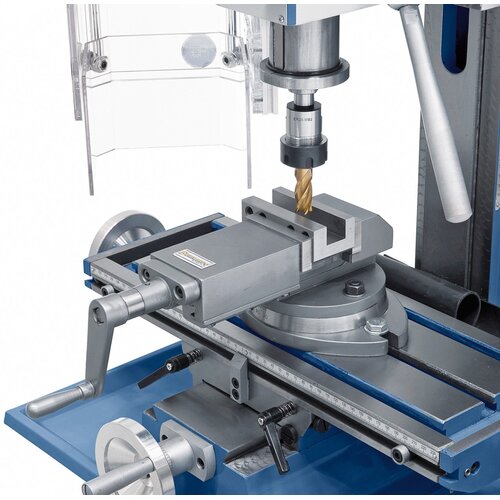

Drilling and milling machine KF 18 Top incl. 3-axis-digital readout DT 40

Art.Nr.: 02-10221The KF 18 Top drilling and milling machine comes complete with a high quality direct current motor. Consequently, there are many advantages such as the high torque at low speed and the almost constant speed during processing. This model is predominantly used among professionals, in model-making as well as for training purposes.

€2,148.00

Availability

Product Properties

- High speed range from 50 - 3000 rpm, 2-step gear box ensures optimal transmission

- Variable speed adjustment, stepless speed change for ideal adjustment to the workpiece

- Model also available with 3-axis digital readout DT 40

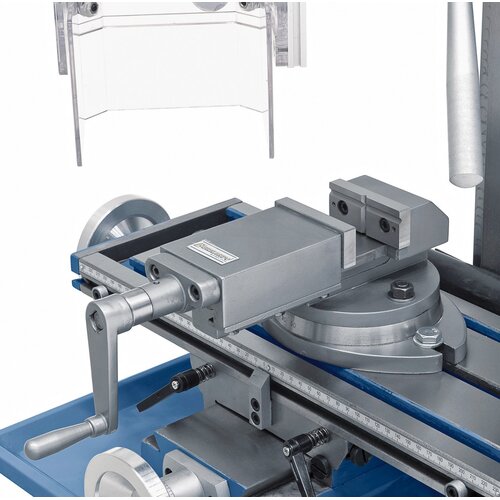

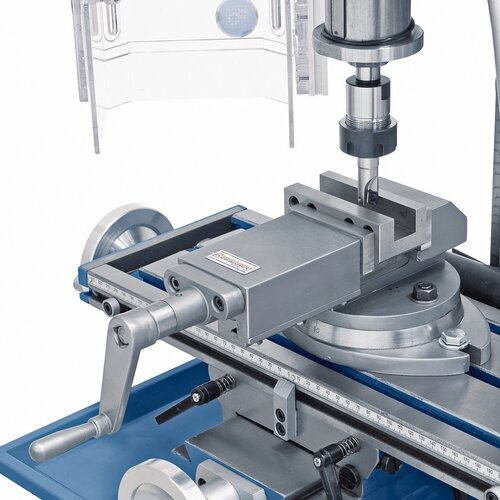

- Oversize cross table features T-slots, high grade surface finish

- Many possible applications, such as groove milling, face milling, reboring, etc.

- Direct current motor for ideal torque at lower speed

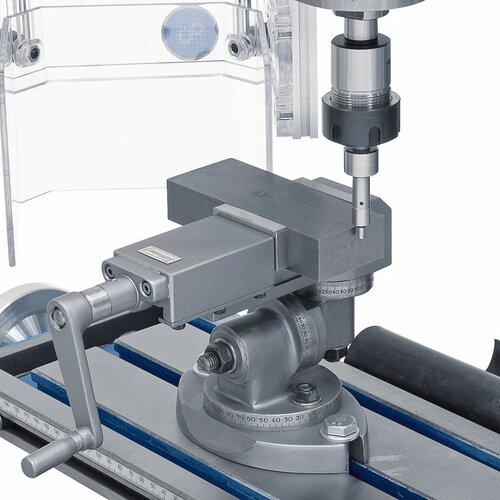

- Mill head tilts to both sides allowing angular boring, milling of bevels, etc.

- Incl. EMC filter, protect electrical equipment against electromagnetic interferences

- Left and right rotation for thread cutting comes standard

- Taper roller bearing guarantees high spindle concentricity (≤ 0,015 mm)

- Dovetail guiding in x-, y- and z-axis, adjustable via gibs

- Spindle adjustment via handle, fine feed via handwheel

Product Specifications

|

Drilling capacity in steel |

18 mm |

|

Face mill capacity max. |

63 mm |

|

End mill capacity max. |

20 mm |

|

Distance spindle to column |

195 mm |

|

Distance spindle to table min./max. |

110/280 mm |

|

Spindle stroke |

52 mm |

|

Spindle speed, stepless |

50 - 1500/100 - 3000 rpm |

|

Spindle taper |

MT 2 |

|

Table size |

500 x 180 mm |

|

Travel (x / y) |

285 / 135 mm |

|

Mill head tiltable |

-90° to +90° |

|

Height adjustment of mill head |

170 mm |

|

T-slot size |

12 mm |

|

Motor power output S1 100% |

0,50 kW / 230 V |

|

Motor power input S6 40% |

0,80 kW / 230 V |

|

Machine dimension (W x D x H)* |

740 x 640 x 850 mm |

|

Weight approx. |

95 kg |

* without stand

Delivery Contents

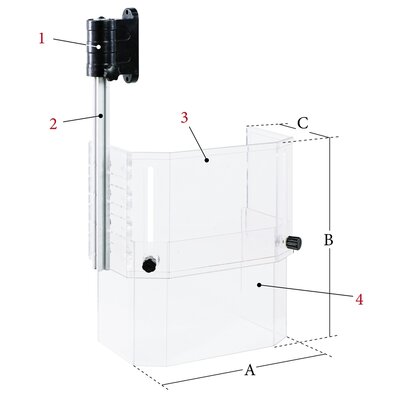

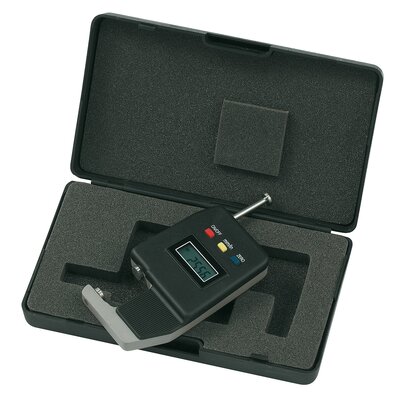

- 3-axis digital readout DT 40

- Drill chuck 3 - 16 mm / B 16

- Drill chuck arbor MT 2 / B 16

- Drawbar M 10

- LED machine light

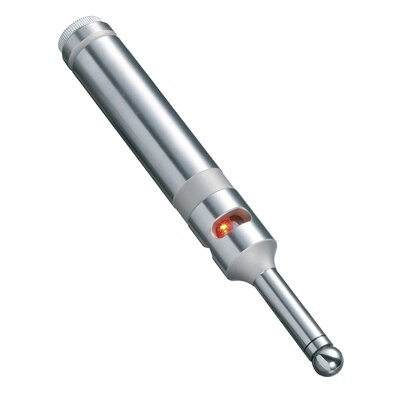

- Digital speed indicator

- Digital spindle stroke indicator

- EMC filter according to CE standard

- Height adjustable protective cover

- Energy chain

- Tools

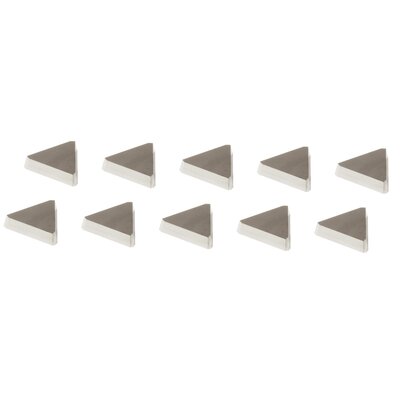

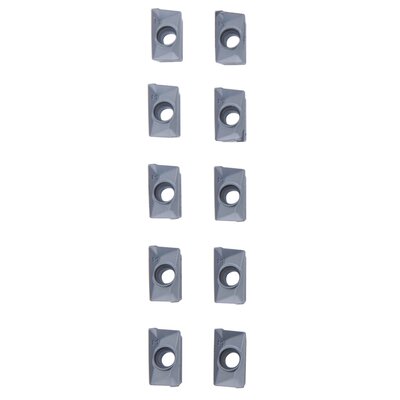

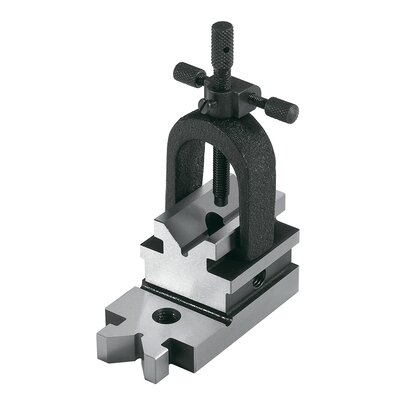

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.