Universal turning lathe Smart 410 x 1000 V-constant *

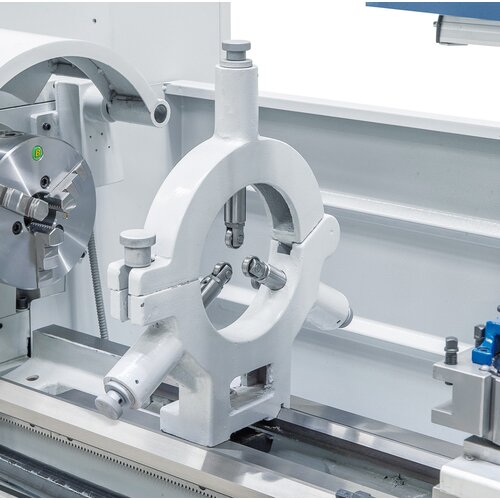

Art. No.: 03-1303XLThe Smart 410 V-constant universal lathe feature a solid construction and practicality. Making this model truly versatile for technical schools, repair shops and training workshops is the standard equipment which comprises all major accessories such as 3-axis digital readout, rests, LED-machine lamp and safety precautions in accordance with CE-standards. Furthermore, this model features the additional feature of “constant cutting speed”, allowing excellent results when processing work pieces with inconsistent diameters.

€18,276.00

Availability

Product Properties

- Constant cutting speed when face turning, spindle speed automatically adjusts to diameter of work piece

- High surface quality due to the constant cutting speed when facing turning

- Grey cast iron machine bed, inductively hardened and precisely polished

- Centrally positioned, practical feed and thread cutting controls (with leadscrew and feed rod)

- State-of-the-art main spindle bearing with high-quality angular ball bearings

- Complete with frequency inverter and 3-axis digital readout including speed indication

- Hardened, polished gear wheels and shafts, even in feed unit

- Clearly arranged, user-friendly, accurate speed and feed change

- Tailstock can be repositioned for taper turning, handwheel feature adjustable scale (0.02 mm)

- Removable bridge allows machining of oversize workpieces

Product Specifications

|

Distance between centers |

1000 mm |

|

Center height |

210 mm |

|

Swing over bed |

420 mm |

|

Swing over gap |

580 mm |

|

Swing over cross slide |

250 mm |

|

Bed width |

250 mm |

|

Spindle bore |

52 mm |

|

Spindle nose fixture |

DIN 55029, D1 - 6 |

|

Speed range, stepless |

30 - 550 / 550 - 3000 rpm |

|

Longitudinal feed |

(17) 0,05 - 1,7 mm/rev. |

|

Cross feed |

(17) 0,025 - 0,85 mm/rev. |

|

Metric thread |

(42) 0,2 - 14 mm |

|

Inch thread |

(45) 2 - 72 threads/1“ |

|

Diameter of tailstock sleeve |

50 mm |

|

Travel of tailstock sleeve |

125 mm |

|

Taper of tailstock sleeve |

MT 4 |

|

Motor power |

5,5 kW (7,5 HP) |

|

Machine dimension (W x D x H) |

1950 x 1000 x 1580 mm |

|

Weight approx. |

1220 kg |

Delivery Contents

- 3-axis digital readout ES-12 S with LCD-display and speed indication

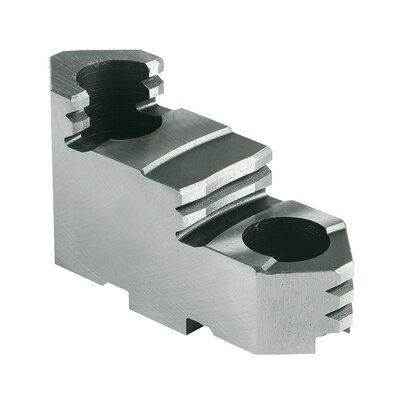

- 3-jaw steel chuck PO3-200 mm / D6

- Face plate 350 mm

- Steady rest - Passage up to max. 130 mm

- Follow rest - Passage up to max. 70 mm

- Foot pedal with brake function according to CE

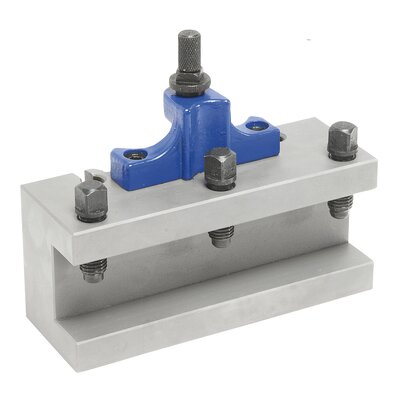

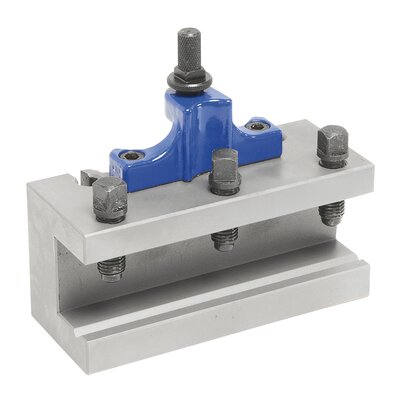

- 40 pos. tool post and holder set with 4 inserts

- Protective device at tool holder

- Micrometer longitudinal fence

- Turret fence with fine adjustment

- Frequency inverter

- Initial filling with Shell Tellus 46

- Coolant device

- Safety clutch

- Thread dial

- LED machine light

- Change gears

- Morse taper drill sleeve

- 2 dead centers

- Splash guard

- Tools

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.