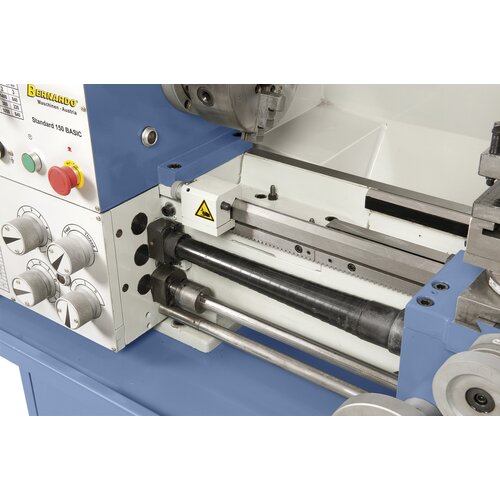

Universal lathe Standard 150 Basic *

Art. No.: 03-1255The Standard 150 Basic is compact precision lathe. The attractive price to performance ratio along with the wide range of accessories makes this model ideal for ambitious amateurs.

€4,428.00

Availability

Product Properties

- Practical machine with lead screw and feed rod for thread cutting and automatic feed

- Removable bridge for processing of workpieces large in diameter

- Rigid prism-shaped bed features additional reinforcements to keep vibrations to a minimum

- Clearly arranged speed and feed control settings, smooth operation and accurate control

- Strongly reinforced prism-shaped machine bed features induction hardened and polished guiding

- Tailstock can be adjusted ± 10 mm to allow taper turning

- Tailstock features single lever clamping, handwheel features adjustable fine scale (0.04mm)

- Tailstock, spindle stock and all guides are re-adjustable

- Top slide with scale (0.02mm) swivels ± 45°

Product Specifications

|

Distance between centers |

1000 mm |

|

Center height |

165 mm |

|

Swing over bed |

330 mm |

|

Swing over gap* |

430 mm |

|

Swing over cross slide |

180 mm |

|

Bed width |

180 mm |

|

Spindle bore |

40 mm |

|

Spindle nose fixture |

DIN 55029, D1-4 |

|

Speed range |

(9) 75 - 1400 rpm |

|

Longitudinal feed |

(40) 0,053 - 1,29 mm/rev. |

|

Cross feed |

(40) 0,013 - 0,31 mm/rev. |

|

Metric thread |

(32) 0,4 - 7 mm |

|

Inch thread |

(36) 4 - 60 threads/1“ |

|

Travel of tailstock sleeve |

110 mm |

|

Taper of tailstock sleeve |

MK 3 |

|

Motor power output S1 100% |

1,5 kW (400 V) |

|

Motor power input S6 40% |

2,2 kW (400 V) |

|

Machine dimension (W x D x H) |

1600 x 700 x 1280 mm |

|

Weight approx. |

455 kg |

* Removable bed length: 220 mm

Delivery Contents

- 3-jaw chuck DK11-160 mm / D4

- Independent chuck 200 mm / D4, according DIN 55029

- Steady rest – Passage up to 60 mm

- Follow rest – Passage up to 60 mm

- Face plate 250 mm

- 4-way tool post holder

- Protective device at 4-way tool post holder

- Safety clutch

- Micrometer longitudinal fence

- Chip tray

- Splash guard

- 2 dead centers

- Thread dial

- Morse taper drill sleeve

- LED machine light

- Change gears

- Motor with magnetic brake according to CE

- Stand

- Tools

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.