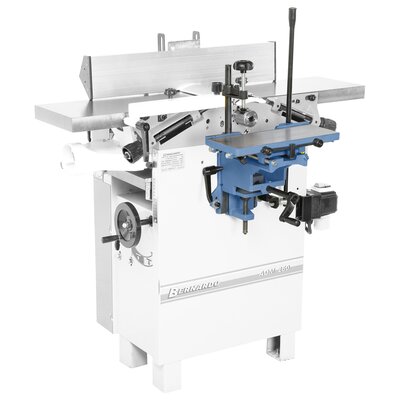

Universal combined machine CU 260 FS - 1600 / 400 V *

Art. No.: 08-1274The CU 260 FS wood processing centre combines several applications on limited space: planing, sawing, milling and drilling. The standard equipment includes a spiral cutter head, four spindle speeds, a digital readout of moulding spindle speed and many more features that make this model unique and unbeatable.

€4,620.00

Availability

Product Properties

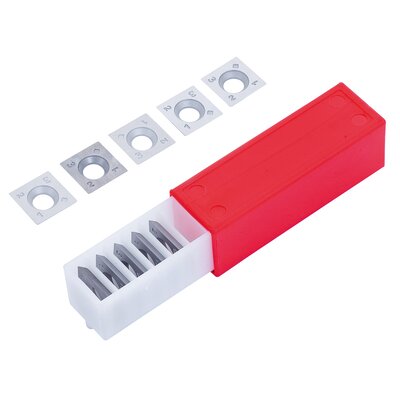

- Reduction of noise level (approx. 50%) due to the standard spiral cutter head and up to 20 times the cutting edge life (results from four-way carbide inserts)

- Advantage of the carbide inserts: If damaged, individual knives can be exchanged or turned

- The carbide blades ensure tear-free planing results and optimal surfaces with any type of wood

- Optional with mortising unit (16 mm capacity) available

- Quick and easy readout of spindle speed on digital display

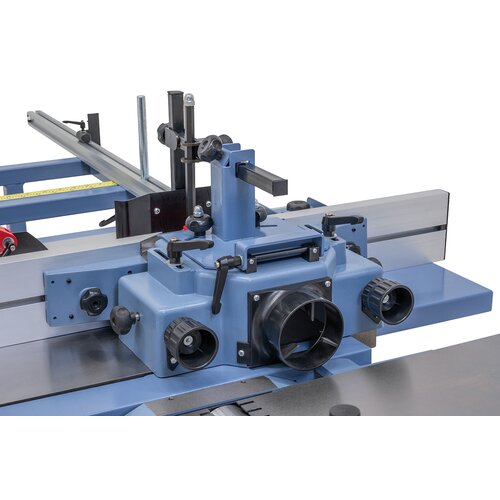

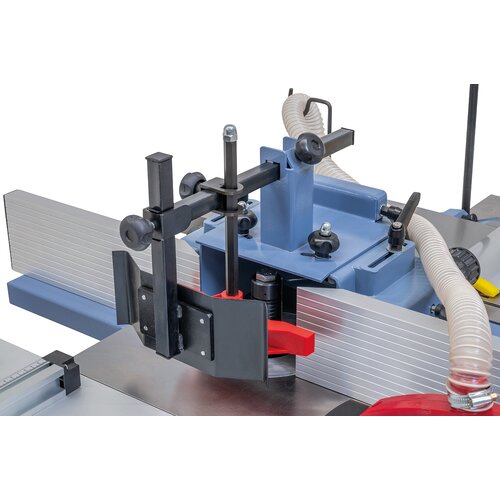

- Solid moulding fence features finely adjustable aluminium fence rails

- Machine body consists of torsion-free combination of steel and grey cast iron

- Smooth running, precise sliding table features hardened, prism-shaped guides

Product Specifications

Dressing slicer

|

Dressing width |

250 mm |

|

table length |

1090 mm |

|

table height |

865 mm |

|

Planer shaft speed |

4000 rpm |

|

HM turning plates |

24 pcs |

|

Planer shaft diameter |

75mm |

|

Dressing |

720 x 130mm |

|

Swivel dressing stop |

90° to 45° |

|

Maximum chip acceptance |

5mm |

|

S1 engine output 100% |

2,0 kW (2,7 hp) |

|

Motor input power S6 40% |

2.8 kW (2.5 hp) |

Dickenplaner

|

table length |

600mm |

|

Hobelbreite |

250 mm |

|

Thickness flow, min/max. |

5 - 185mm |

|

Maximum chip acceptance |

1.8 mm |

|

feed rate |

8 m/min |

|

Extraction port Ø |

100 mm |

Long hole drilling device (available as an option)

|

Drilling table size |

370 x 150 mm |

|

Westcott drill chuck |

0-16mm |

|

Max. drilling depth |

90mm |

|

Bohrbreite |

160mm |

|

height adjustment |

85mm |

circular saw

|

Table dimensions |

900 x 345 mm |

|

table height |

865 mm |

|

Cantilever table |

600 x 460 |

|

format table |

1600 x 240 mm |

|

Trim length |

1600 mm |

|

Max. saw blade diameter |

250 x 30 mm |

|

Max. cutting height 90°/45° |

80/60 mm |

|

Cutting width at the parallel stop |

910 mm |

|

Main saw blade speed |

4750 rpm |

|

Extraction port Ø |

100 mm |

|

S1 engine output 100% |

2.2 kW (1.5 hp) |

|

Motor input power S6 40% |

3,0 kW (4,0 hp) |

Milling machine

|

spindle diameter |

30mm |

|

height adjustment |

110mm |

|

Milling table opening |

170mm |

|

Clamping length |

90mm |

|

Max. tool diameter |

|

|

- when profiling |

150mm |

|

- when cutting cones |

150mm |

|

spindle speed |

1400/4000/6000/8000 rpm |

|

S1 engine output 100% |

1,5 kW (2,0 hp) |

|

Motor input power S6 40% |

2.1 kW (2.8 hp) |

|

voltage |

400 V |

|

Machine dimensions (W x D x H) |

1600 x 2340 x 1150 mm |

Delivery Contents

- Spiral cutter head with 24 pcs. TCT-blades

- Replacement TCT-blades (5 pcs.)

- Planer fence

- Downholder

- Mitre fence

- Moulding fence

- Protective cover with dust extraction outlet

- Connector tube with Y-piece

- Aluminium fence with stop

- Sawblade 250 x 3,2 x 30 mm / 24T

- Digital speed indication of moulding spindle

- Push stick

- Tools

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.