Universal combined machine CF 410 F - 2600 *

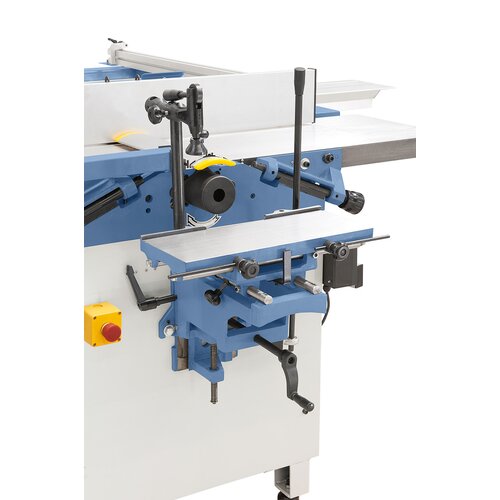

Art. No.: 08-1296The CF 410 F - 2600 wood processing centre offers an enormous number of applications and best possible performance for professional users. The combination of planer, thicknesser, circular saw, spindle moulder and mortising unit all in one, gives a wide range of applications yet requires minimum space.

€9,132.00

Availability

Product Properties

- Powerful drive motors guarantee optimal results even at continuous operation

- Solid planer fence with prism guide, tiltable from 90º to 45º

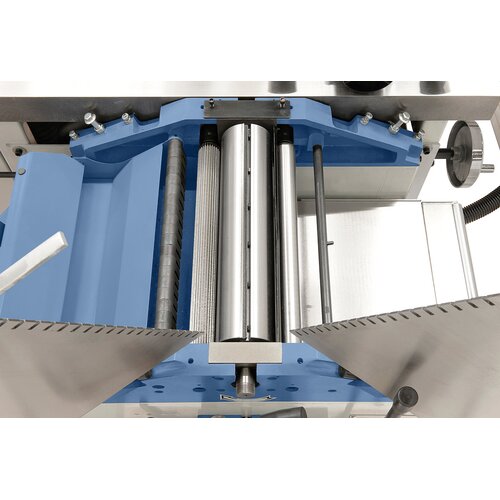

- Maintenance-free 4-knife cutterblock with planer knives in HSS – 18 % quality

- Square table with roller for convenient handling of large workpieces

- All aluminium parts (sliding table, fences,...) are anodized

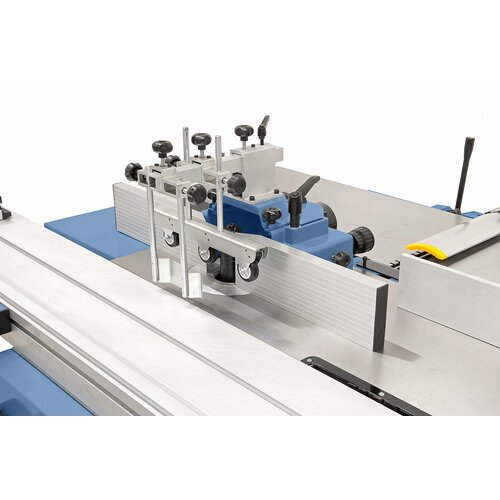

- Moulding fence features aluminium fence rails on both sides incl. fine adjustment

- Large, grey cast-iron moulder unit, tilts from 0° to -45°

- Milling spindle speed on digital display allows for quick and easy readout

- Extractable telescopic fence with end stop and fine adjustment

- Solid moulding fence with dust extraction outlet 100 mm

- Dynamically balanced milling spindle ensures precise running

Product Specifications

|

Planer |

|

|

Planer width |

410 mm |

|

Table length |

1600 mm |

|

Table height |

950 mm |

|

Shaft rotation speed |

4100 rpm |

|

Cutter knives |

4 Stk. |

|

Planer shaft diameter |

95 mm |

|

Planer fence |

1100 x 150 mm |

|

Fence tiltable |

90° bis 45° |

|

Max. cutting depth |

5 mm |

|

Motor power output S1 100% |

2,2 kW (3,0 HP) |

|

Motor power input S6 40% |

3,0 kW (4,0 HP) |

|

Thicknesser |

|

|

Table length |

750 / 930* mm |

|

Working width |

405 mm |

|

Working thickness, min/max. |

5 - 230 mm |

|

Max. cutting depth |

5 mm |

|

Feed speed |

6 m/min |

|

Dust extraction outlet |

100 mm |

|

Mortising unit |

|

|

Table size |

450 x 190 mm |

|

Westcott drill chuck |

0 - 16 mm |

|

Max. drill depth |

125 mm |

|

Drill width |

175 mm |

|

Height adjustment |

115 mm |

|

Circular saw |

|

|

Table size |

1300 x 380 mm |

|

Table height |

950 mm |

|

Table extension |

310 x 350 mm |

|

Square table with roll |

880 x 580 mm |

|

Sliding table |

2600 x 270 mm |

|

Cutting length |

2600 mm |

|

Max. sawblade diameter |

315 x 30 mm |

|

Max. cutting height 90° / 45° |

100 / 80 mm |

|

Cutting width on rip fence |

730 mm |

|

Speed main sawblade |

4500 rpm |

|

Speed scoring sawblade |

8500 rpm |

|

Scoring sawbalde |

90 x 20 mm |

|

Dust extraction outlet |

95 mm |

|

Motor power output S1 100% |

3,0 kW (4,0 HP) |

|

Motor power input S6 40% |

4,2 kW (5,7 HP) |

|

Spindle moulder |

|

|

Spindle diameter |

30 mm |

|

Height adjustment |

125 mm |

|

Spindle tiltable |

0° to -45° |

|

Table opening |

80 / 110 / 150 / 200 mm |

|

Working length of spindle |

110 mm |

|

Max. tool diameter |

180 mm |

|

Spindle speed |

1800 / 3000 / 6000 / 9000 rpm |

|

Dust extraction outlet |

100 mm |

|

Motor power output S1 100% |

2,8 kW (3,8 HP) |

|

Motor power input S6 40% |

3,9 kW (5,3 HP) |

|

Voltage |

400 V |

|

Machine dimension (W x D x H) |

2600 x 2800 x 1280 mm |

|

Weight approx. |

765 kg |

* with thicknesser table extension

Delivery Contents

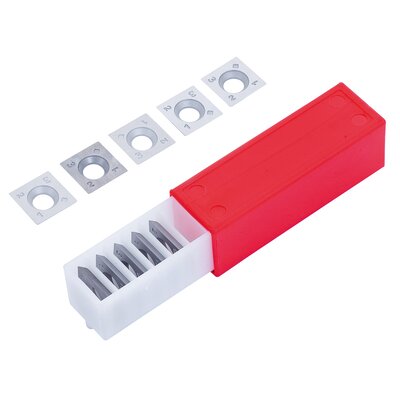

- Cutter knives 410 x 30 x 3 mm

- Thicknesser table extension with roll

- Mortising unit

- Westcott drill chuck 0 – 16 mm

- Eccentric holder

- Carbide sawblade 315 x 3,0 x 30 mm / 40T

- Scoring sawblade 90 x 3,0 x 20 mm / 12T

- Protective cover with dust extraction outlet and tube

- Mitre fence with eccentric holder

- End stop

- Table extension

- Telescopic fence with stop

- Square table with roll

- Moulding fence

- Spindle with left and right turning

- Digital speed indication of moulding spindle

- Push handle

- 2 pcs. push stick

- Tools

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.