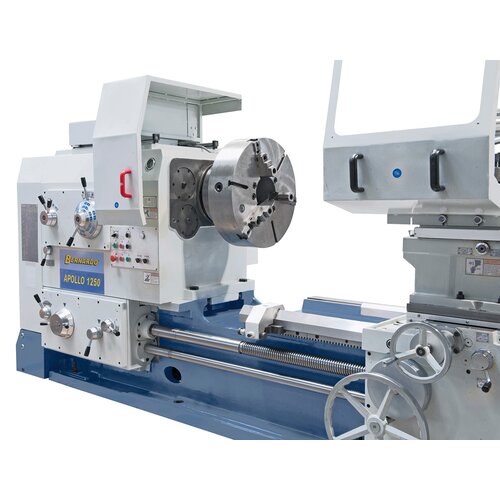

Heavy lathe Apollo 1250 x 3000 incl. 3-axis-digital readout **

Art. No.: 03-1376XLPrice on request

Request product nowAvailability

Product Properties

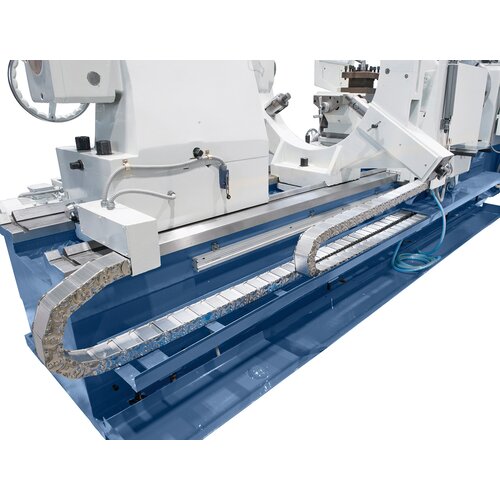

- The machine bed is buckling resistant and vibration-free which enables precise turning

- The transmission of the rotary motion (forwards / backwards) takes place via a drive shaft with hydraulic clutch

- The large dimensioned guideways are inductively hardened and grounded

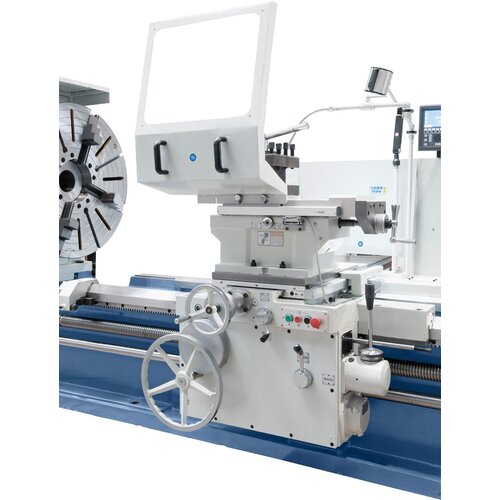

- The cast-iron headstock with large wall thickness and compact construction guarantees rigidity and stability

- Hardened, polished gear wheels and shafts, even in feed unit

- For machining a wide variety of workpieces, the machine has a speed range of 3,15 - 400 rpm with 36 speeds

- Mechanic coupling allows soft start of the main spindle

Product Specifications

|

Distance between centers |

3000 mm |

|

Turning diameter |

|

|

over bed |

1250 mm |

|

over support |

900 mm |

|

Travel |

|

|

x-axis |

630 mm |

|

z-axis |

2800 mm |

|

z1-axis |

300 mm |

|

Workpiece weight max. |

6000 kg |

|

Bed with |

755 mm |

|

Tilting range top slide |

± 180° |

|

Spindle speeds (forward / backward) |

(24) 3,15 - 315 / (12) 5 - 400 rpm |

|

Spindle bore |

130 mm |

|

Spindle nose fixture |

ISO A2-15 |

|

Feed |

|

|

x-axis | z-axis | z1-axis |

0,064 - 12 mm/rev. |0,032 - 6 mm/rev. | 0,016 - 3 mm/rev. |

|

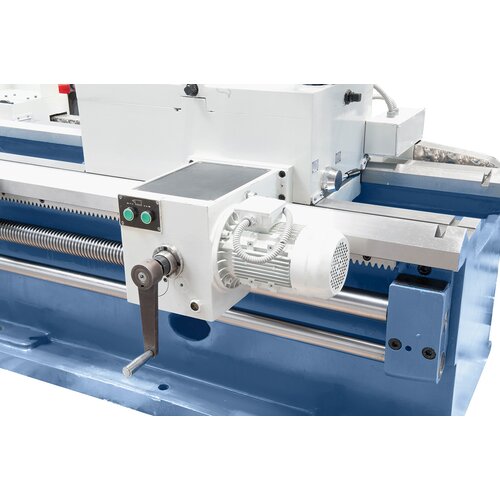

Rapid feed |

|

|

x-axis | z-axis |

1870 mm/min | 3740 mm/min |

|

Thread cutting |

|

|

metric | diametric |

(45) 1 - 120 mm | (42) 30 - 1/4 DP |

|

Modul | whitworth |

(46) 0,5 - 60 mm | (48) 0,5 - 60 GPZ |

|

Tailstock sleeve taper / Ø |

metric 80 / 160 mm |

|

Tailstock sleeve stroke |

300 mm |

|

Tailstock cross adjustment |

± 2,5 mm |

|

Motor power |

22 kW |

|

Length x Width |

6,1 x 1,88 m |

|

Height |

1,92 m |

|

Weight approx. |

11.550 kg |

Delivery Contents

- 3-axis digital readout ES-12 V with LCD display

- Independent chuck 1000 mm

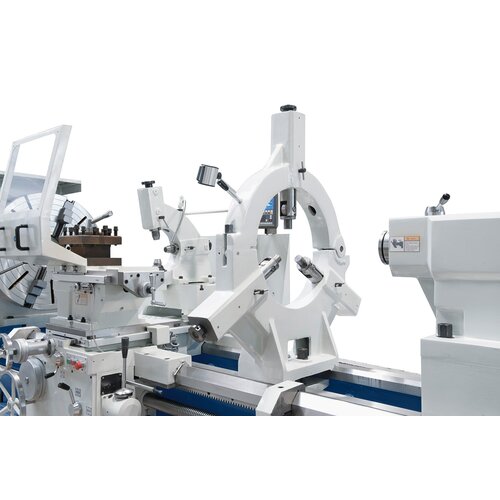

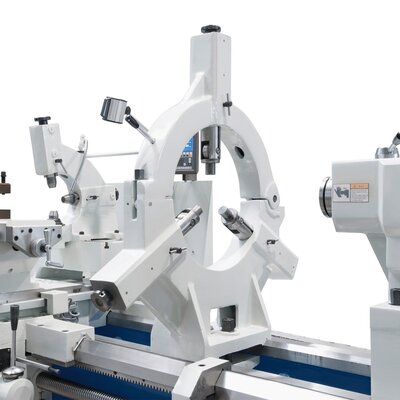

- Steady rest - Passage diam. 50 - 590 mm

- Follow rest - Passage diam. 50 - 220 mm

- Motorized tailstock

- Dead centers

- Cental lubrication

- Initial filling with Shell Tellus 46

- 4-way tool post holder

- Protective cover at 4-way tool post holder

- Coolant device

- LED machine light

- Morse taper drill sleeve

- Anchor bolts

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.