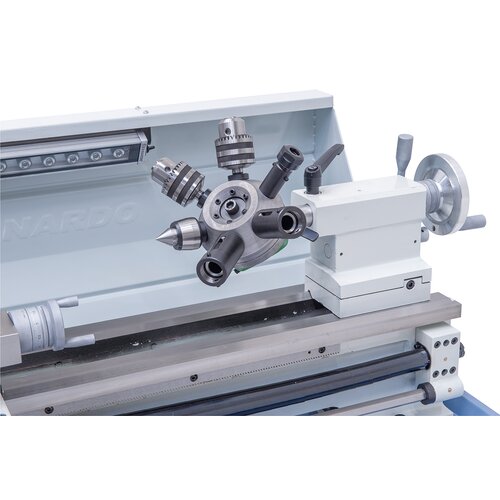

Precision lathe Profi 750 Vario / 230 V

Art. No.: 03-11790The Vario-lathe Profi 750 Vario feature a large range of standard accessories (for instance DC-motor with frequency inverter, main spindle bearing in P5-quality, micrometric longitudinal fence, safety clutch, LED machine light,....) making this model ideal for users with high expectations. For reducing the non-productive time, the model is also available with a 2-axis digital readout.

€3,708.00

Availability

Product Properties

- Three -phase motor with frequency inverter for higher performance and high torque

- Complete with 38 mm spindle bore to allow processing of large shaft diameters

- Stepless speed adjustment as part of standard accessories, set speed can be read on digital display

- Wide range of applications: precision mechanics, training and education, etc.

- Feed settings are logically arranged, easy to control with top accuracy

- Suitable for processing of steel, non-ferrous metals and plastics

- Prism bed with large support surface, inductively hardened and polished

- Precise spindle bearing with two adjustable precision taper roller bearings

- High concentricity of spindle nose – better than 0.015 mm

- Practical, solid machine with leadscrew and feed rod

Product Specifications

|

Distance between centers |

750 mm |

|

Center height |

140 mm |

|

Swing over bed |

280 mm |

|

Spindle bore |

38 mm |

|

Spindle nose fixture |

DIN 55029, D1-4 |

|

Speed range, stepless |

75 – 500 / 300 – 2000 rpm |

|

Longitudinal feed |

(15) 0,07 – 1,0 mm/rev. |

|

Cross feed |

(15) 0,017 – 0,25 mm/rev. |

|

Metric thread |

(18) 0,2 – 3,5 mm |

|

Inch thread |

(21) 8 – 56 threads/1“ |

|

Travel of tailstock sleeve |

90 mm |

|

Taper of tailstock sleeve |

MT 3 |

|

Motor power output S1 100% |

1,5 KW / 230 V |

|

Motor power input S6 40% |

2,2 kW / 230 V |

|

Machine dimension (W x D x H)* |

1400 x 730 x 520 mm |

|

Weight approx. |

220 kg |

* without stand

Delivery Contents

- 3-jaw chuck DK11-160 mm / D4

- Dead centers

- Change gears

- 4-way tool post holder

- Safety clutch

- Micrometer longitudinal fence

- Cross slide with top support

- Frequency inverter

- Digital speed indication

- LED machine light

- Chuck guard

- Splash guard

- Leadscrew cover

- Tools

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.