Precision lathe Profi 550 WQ / 400 V

Art. No.: 03-1135The Profi 550 WQ is a top-quality lead screw lathe constructed according to DIN-standards. Special features of these models include the large longitudinal feed with 6 settings and the cross feed.

€2,280.00

Availability

Product Properties

- Comes complete with lead screw for thread cutting and automatic longitudinal feed

- Solid machine bed with inductively hardened and polished guides

- High-quality tapered rollerbearings ensure high concentricity of spindle nose (≤ 0,015 mm)

- Temperature monitoring incl. warning light protect motor against overload

- Tailstock can be adjusted for taper turning

- User-friendly arrangement of control elements

- Guides adjustable via gibs

- Spindle features 2 adjustable tapered roller bearings (P5-quality)

- Longitudinal and cross feed come standard

- Protective switch with undervoltage release

Product Specifications

|

Distance between centers |

550 mm |

|

Center height |

125 mm |

|

Swing over bed |

250 mm |

|

Bed width |

135 mm |

|

Spindle bore |

26 mm |

|

Taper at spindle bore |

MT 4 |

|

Speed range |

(6) 125 - 2000 rpm |

|

Longitudinal feed |

(6) 0,06 - 0,32 mm/rev |

| Cross feed |

(4) 0,03 - 0,075 mm/rev |

|

Metric thread |

(18) 0,2 - 3,5 mm |

|

Inch thread |

(21) 8 - 56 threads/1" |

|

Travel of tailstock sleeve |

70 mm |

|

Taper of tailstock sleeve |

MT 2 |

|

Motor power output S1 100% |

0,75 kW / 400 V |

|

Motor power input S6 40% |

1,0 kW / 400 V |

|

Machine dimensions (W x D x H)* |

1210 x 610 x 450 mm |

|

Weight approx. |

120 kg |

* without stand

Delivery Contents

- 3-jaw chuck DK11-125 mm

- Flange 125 mm

- Cross slide with top support

- Dead centers

- Thread dial

- Change gears

- 4-way tool post holder

- Chuck guard

- Chip guard

- Leadscrew cover

- Tools

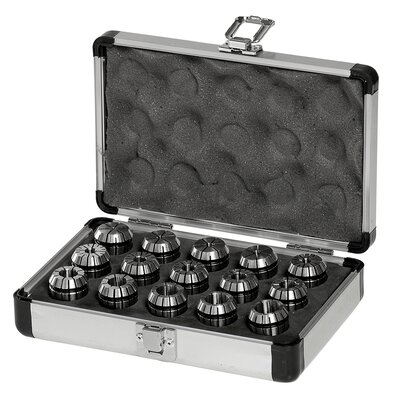

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.