Univerzální soustruh Master 400 x 1500 s 3osé digitálního odměřování ES-12 V

Art. No.: 03-1289XL0The Master 400 is a solidly constructed universal lathe, offering a wide range of applications. Features of this model include the large turning diameter of 400 mm and the 52 mm spindle bore. Its construction (design, performance, feeds etc) covers all needs for training purposes, as well as for tool shops and repair shops.

10 668,00 €

Availability

Product Properties

- Ideal for processing of steel, non-ferrous materials and plastics

- Electro-magnetic foot brake reduces downtime

- Hardened and polished gears also in feed drive

- Practical, solid machine featuring a leadscrew and feed rod

- Grey cast-iron machine bed, inductively hardened and precisely polished

- State-of-the-art spindle bedding with high-quality, angular ball bearings

- Machine base in heavy cast iron construction

- Tailstock can be adjusted ± 5 mm for taper turning

- Ideal for technical colleges, repair shops and training purposes

- Easy, smooth and precisely adjustable speed and feed settings

- Chip tray extract to front, keeping space requirements to a minimum

- Removable bridge for processing of workpieces with a large diameter

- Optimal price-benefit ratio, modern design

- Serially equipped with safety clutch

Product Specifications

|

Distance between centers |

1500 mm |

|

Center height |

200 mm |

|

Swing over bed |

400 mm |

|

Swing over gap |

560 mm |

|

Swing over cross slide |

240 mm |

|

Bed width |

210 mm |

|

Spindle bore |

52 mm |

|

Spindle nose fixture |

DIN 55029, D1-5 |

|

Speed range |

(12) 45 - 2000 rpm |

|

Longitudinal feed |

(27) 0,06 - 2,78 mm/rev. |

|

Cross feed |

(22) 0,01 - 0,72 mm/rev. |

|

Metric thread |

(36) 0,8 - 14 mm |

|

Inch thread |

(30) 2 - 28 threads/1“ |

|

Diameter of tailstock sleeve |

45 mm |

|

Travel of tailstock sleeve |

100 mm |

|

Taper of tailstock sleeve |

MT 4 |

|

Motor power |

2,0 kW / 2,4 kW |

|

Machine dimension (W x D x H) |

2360 x 800 x 1600 mm |

|

Weight approx. |

930 kg |

Delivery Contents

- 3-axis digital readout ES-12 V with LCD-display

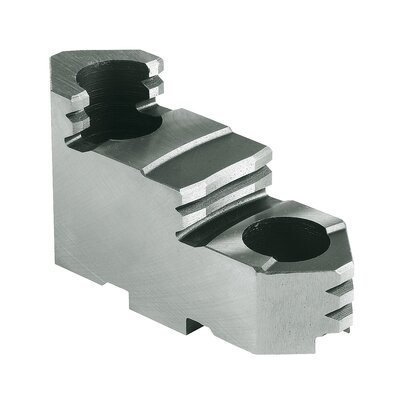

- 3-jaw chuck DK11-200 mm / D5

- Independent chuck 200 mm / D5, according DIN 55029

- Steady rest - Passage up to max. 90 mm

- Follow rest - Passage up to max. 70 mm

- Coolant device

- Initial filling with Shell Tellus 46

- Extractable chip tray

- Face plate 320 mm

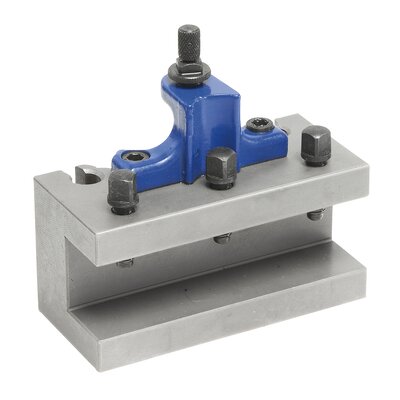

- 4-way tool post holder

- Protective device at 4-way tool post holder

- Safety clutch

- Micrometer longitudinal fence

- Thread dial

- LED machine light

- Morse taper drill sleeve

- Change gears

- 2 dead centers

- Foot pedal with brake function according to CE

- Motor with magnetic brakce according to CE

- Tools

Suitable accessories

Für jeden Zweck das Richtige

ENTDECKEN SIE UNSERE KATALOGE

In unseren Katalogen erhalten Sie umfangreiche Informationen zu unseren Maschinen. Werfen Sie einen blick hinein, es lohnt sich.